Equipment

3D printer for metal |

|

|---|---|

|

Metal 3D printing has a unique position in modern product development. It enables direct manufacturing of complex parts for end use and facilitates machining using conventional manufacturing technologies, reducing costs and reducing production time. This technology, known as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), combines manufacturing flexibility with 3D printing with mechanical metal properties to achieve optimum stiffness / weight ratio. 3D metal printing technology can be used for any application involving complex metal parts, from cooling channel molds to lightweight aircraft structures. The most commonly used materials are Titanium (TiAl6V4), Aluminum (AlSi10Mg), Stainless Steel (316L or 1.4404), Inconel (IN718). |

| Computer metrology tomograph | |

|---|---|

|

Computer metrology tomograph enables to assess internal structures of complicated machine parts produced by means of additive technologies. Measuring and control tasks using X-ray images can be successfully performed with a computerized tomography system. Traditional coordinate measuring technology offers only restricted approach, hidden structures can only be measured after time-consuming component destruction by layers. Computer metrology tomograph provides a unique and sophisticated technology to assess a large number of characteristics, the measurements are highly accurate and time to acquire the data is much faster compared to the touch metering method. |

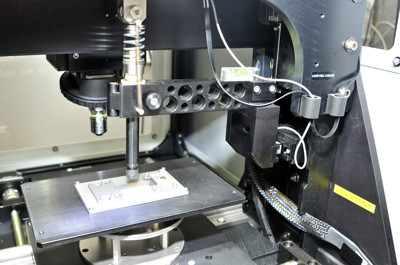

| Contactless vibration measurement | |

|---|---|

|

The apparatus allows to monitor the deformation field of dynamically loaded 3D complicated structures. Contactless vibration measurement based on the principle of laser vibrometers offers unique advantages compared to the use of traditional triaxial accelerometers. It can be successfully utilized in applications where the use of accelerometers is unsuitable or impossible, e.g. when measuring small objects, measuring hot surfaces, measuring inaccessible parts of a measured object or measuring in a radioactive or "high-voltage" environment. The principle of contactless vibration measurement can also be successfully used in the field of acoustics and electroacoustics. |

| Biaxial Testing Machine for Biaxial Tensile Tests | |

|---|---|

|

Biaxial Testing Machine for Biaxial Tensile Tests (CTU) is designed for obtaining material characteristics of both standard materials and composite materials for use in aircraft engine design. On the basis of measured experimental data it is possible to refine constitutive relations describing the behavior of studied structural materials in both the linear and nonlinear continuum mechanics. |

| Tribometer | |

|---|---|

|

It allows to measure tribological parameters such as the friction coefficient, frictional force, abrasion between the surfaces of bodies that are in contact with each other. |

| Servo-hydraulic vertical dynamic axial torsion machine is designed for static and cyclic materials testing. | |

|---|---|

|

The knowledge of material properties and its behavior during stress are important part of a certification process for new

aircraft structures. In aerospace engineering, fatigue tests play an important role since material fatigue presents a very

high-risk factor. |

| Computing cluster – high performance server and storage | |

|---|---|

|

To accommodate the needs for functional complex CAE applications (fluid dynamics simulation applications), it was necessary to build a powerful compute cluster.

The solution is based on HPE servers DL360 Gen10 (total 44 ks) and DL560 Gen10 (in number 4) — all equipped with Intel

Xeon Gold processors (specifically 2nd Generation Intel Xeon Scalable Processors, Cascade Lake) and storage Infortrend ESDS

1016RC G2 disk array. |

![[design/2014/cvut-logo-en-blue.png]](https://www.fs.cvut.cz/content/images/design/2014/cvut-logo-en-blue.png)

![[design/2014/cvut-logo-print.jpg]](https://www.fs.cvut.cz/content/images/design/2014/cvut-logo-print.jpg)