LRI-AAST: L1 laboratory: DYNO and CORE test cells

| Lab | Equipment | Application |

|---|---|---|

| L1 | DYNO – dynamometric test cell for turboprop engines without a propeller system and a reducer | A power output of up to 3300 kW allows to monitor and capture not only the vibration characteristics of each part of the aviation engine but also the characteristics of all engine operating parameters (temperature and pressure fields, power, noise, consumption, etc.) for turboprop engine research and testing activities at a stationary site. |

| CORE test station | The core test station is intended for research of processes in the combustion chambers of turboprop engines and their influence on the dynamic characteristics of the engines. CORE is equipped with a fixed test table, a removable cradle, a linear bearing/thrust measurement, an oil cooling system, a transport trolley, an inlet silencer, a secondary inlet, a heating inlet, etc. |

Location

Location

Dynamometric test cell for turboprop engine and the experimental core test cell for turboprop engine laboratory are located in Prague 9 – Letnany. The test cells share supporting infrastructure including conference room, control room, fuel and LPG management, compressors, exhaust management.

DYNAMOMETRIC TEST CELL

Paratemeters

| Dynamometer | |

|---|---|

| Maximum braking power of dynamometer Froude Hofmann RF47AVGT s/n: FT8042760 |

3281 kW (4400 BHP) |

| Maximum revolute speed | 3500 min-1 |

| Maximum torque | 10 kNm |

| Control system of dynamometer | |

| Froude Hofmann TEXCEL VX100, s/n: 8042845/1 | - |

| Accessories | |

| Air preheating power for LPG engine by heater | 1 MW |

| Reciprocating compressor with water separator and air tank | 11 kW/500 liters |

| Low frequency data measurement (LF DAQ) | |

| Number of thermoelectric temperature sensors | 400 pcs |

| Number of pressure sensors | 304 pcs |

| Number of pressure sensors for liquids | 40 |

| Number of vibration sensors | 32 pcs |

| Number of platinum resistance thermometers | 4 pcs |

| Number of channels for strain gauges | 20 pcs |

| Number of channels for analog signals (voltage / current) | 64 pcs |

| High frequency data measurement (max. 200 kS/s) | |

| Number of channels for accelerometers | 48 pcs |

| Number of universal channels | 72 pcs |

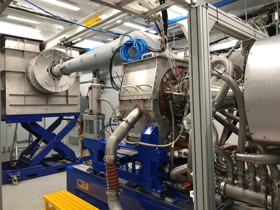

Dynamometric test cell for turboprop engine, located in Prague 9 – Letnany, is a state-of-the-art testing laboratory of aircraft engines with a power output of up to 3300 kW allowing to monitor and capture not only the vibration characteristics of each part of the aviation engine but also the characteristics of all engine operating parameters (temperature and pressure fields, power, consumption, noise, etc.) site for turboprop engine research and testing at a stationary site.

CORE TEST CELL

Paratemeters

| Category | Sub-category | Unit | Reference engine |

|---|---|---|---|

| Engine Core Weight | Dry | Lbm | 445 - 775 |

| Engine Core Weight | Wet | Lbm | 460 - 870 |

| Engine Core Diameter | inch | 15 - 23 | |

| Engine Core Length (without accessories) | inch | 50 - 75 | |

| Engine Core C.G. Locations – installed accessories | inch | 2,56 – 3,61 | |

| Engine Core Airflow | Lbm/sec | 8,1 – 11,5 | |

| Engine Core Speed | 100% Core Speed Rotation | rpm | 20000 - 50000 |

| Exhaust Gas Temperature | Core only | °F | up to 2000 |

| Engine Thrust (nozzle) | lbf | 1250 - 1800 | |

| Engine Core mounting | Qty of mounts | - | 3 - 4 |

| Fuel Consumption | Take Off | Lb/h | 494 - 900 |

| Noise level of engine core | Take Off | dBA | up to 145 |

The experimental core test cell for turboprop engine laboratory located in Prague 9 - Letňany offers an outstanding facility to research and investigate the processes taking place in the combustion chamber of a turboprop engine and their influence on the dynamic characteristics of engines. The laboratory state-of-the-art HW and SW equipment allows to observe and analyse the vibration characteristics of individual parts of the reduced motor (without the propeller and the speed reducer).

![[design/2014/cvut-logo-en-blue.png]](https://www.fs.cvut.cz/content/images/design/2014/cvut-logo-en-blue.png)

![[design/2014/cvut-logo-print.jpg]](https://www.fs.cvut.cz/content/images/design/2014/cvut-logo-print.jpg)